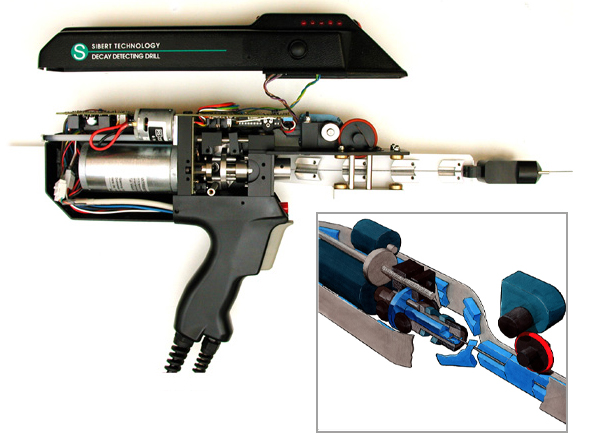

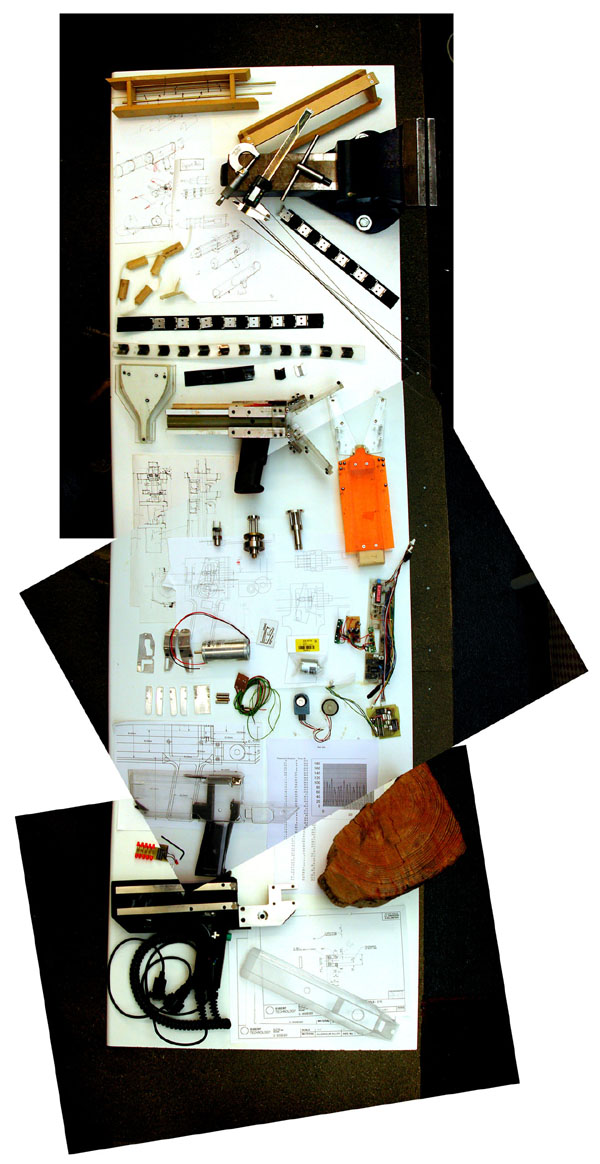

1) Probe support.

Being only one millimetre in diameter, and up to one metre long, the flexible probe needs to be supported when not in the timber. Early telescopic solutions were fraught with problems in terms of both the complexity of servicing and the inability to cope in an often-dirty environment.

The bold step was taken to invent a 'three dimensional zip' support. When together, the two halves of the zip sandwich the probe and interlock to form a rigid beam. When separated, the zip halves are flexible enough to bend around the body of the instrument.

This had the benefits of a huge reduction in maintenance costs; the ability to use any length of probe; and, not least, a point of interest that continually draws customers in and engenders faith in the product.